PRODUCTS IN CATEGORY

Humid compressed air poses a huge risk not only through corrosion in pneumatic tools, but above all it leads to contamination caused by moisture and deterioration of quality throughout the production process. It can cause the freezing of pipelines in large industrial plants (and thus a decrease in plant capacity) or damage (unsuitable for use) to entire production batches – e.g. in the pharmaceutical or food industry.

We offer industrial dehumidifiers from the German manufacturer BEKO-Technologies DRYPOINT and EVERDRY, which thanks to the increased operational safety (reliability) go far beyond market standards.

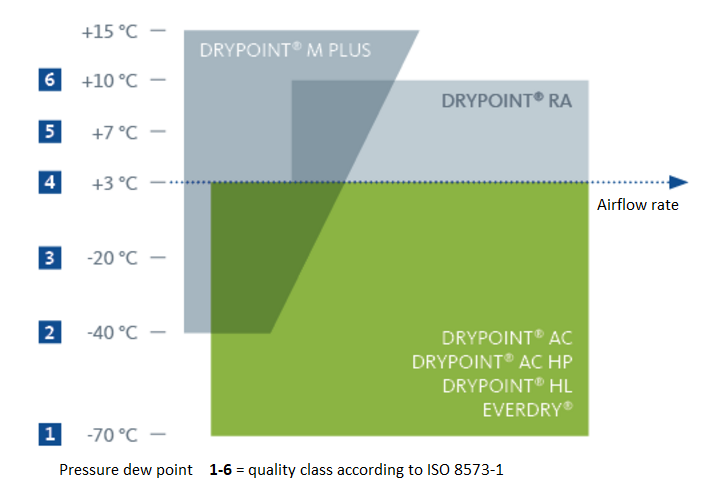

The right choice of dryer is crucial for energy efficiency and compressed air quality. The criteria for selecting a dryer are: degree of drying, efficiency, and air quality (class).

We distinguish between three methods of drying compressed air:

- DRYPOINT RA refrigeration dryer

- adsorption dryer – DRYPOINT AS, HL and EVERDRY

- membrane dryer

Efficiency graph of individual types of dehumidifiers:

We help our customers to choose the right compressed air dryer for their process requirements and the conditions in their plant.

From 4 to 350 bar

From +2°C to +50°C

From +5°C to +100°C

From -70 to +7

From 20 m3/h

BEKOMAT (automatic condensate drain)

- Refrigeration dryer – Drypoint RA – the most economical method of dehumidification (allows for a pressure dew point of +3oC

- Cold and hot regenerated adsorption dryer – Drypoint AC and EVERDRY (allows for a pressure dew point of -70oC) – for the most demanding processes

- The Drypoint M membrane dryer is the most compact solution, suitable for discontinuous use at the reception point or for treating part of the compressed air stream (the dew point can be adjusted within a certain range.