PRODUCTS IN CATEGORY

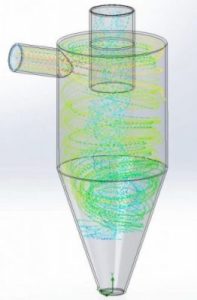

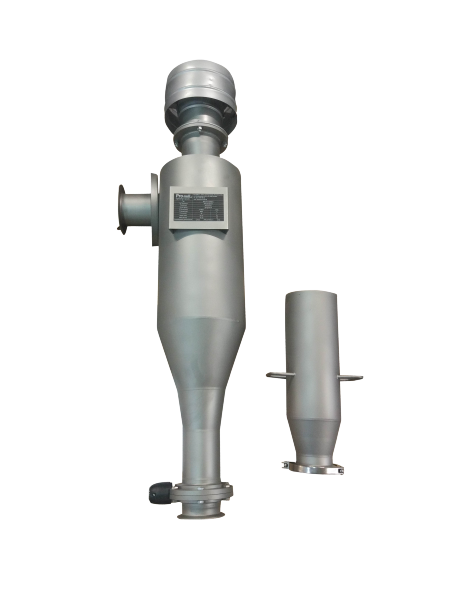

The cyclone separator, also called a centrifugal separator, is used to separate solid particles from the gas stream. This separation is caused by the introduction of a gas stream into a vortex movement, during which the particles are subjected to centrifugal force, causing the dust to be rejected towards the walls of the device. As a result of collisions with the cyclone walls, the particles lose energy and fall to the bottom by gravity. Our cyclone can operate on existing process lines with forced gas circulation. There are also versions with own extractor (turbine with electric motor inside the device).

We also manufacture equipment adapted for the food industry with the possibility of CIP. We select the industrial cyclones we perform according to individual customer needs, ensuring that all process requirements are met.

Cyclones have many advantages:

- simple and compact design

- no moving parts (except for cyclones with turbine)

- High temperature and high pressure capability

- low running costs

- uncomplicated operation

- high efficiency

- high scalability

- possibility to work with very high flows

- CIP capability.

- It should be remembered, however, that in order for the cyclone to work effectively, a constant flow of the value for which the device was designed is required.

Cyclones with a tangential inlet are most often used, however, the dusty gas stream can be introduced into the device in several ways, e.g. axial inlet. The most characteristic feature of Pro-mill’s axial cyclones is the placement of the inlet and outlet in one axis (the so-called “in-line” construction). This device uses the same separation mechanism as the cyclones with tangential inlet. In this case, the gas enters the centrifugal movement passing through uniquely profiled blades. Axial cyclones are mainly used to separate liquid drops from the gas stream. They can also be successfully used to separate solid particles. We manufacture axial cyclones in many configurations. They can be equipped with a dust container or prepared for food industry and subjected to CIP. The product is made of plastic or acid resistant steel. The compact design and small size allow to build many cyclones in one housing. Devices built in this way are called a multi-cyclone, whose construction allows to clean very large gas streams while maintaining high efficiency. Multicyclones can also be prepared for CIP procedure.

- AISI 304,

- AISI 316

- Satin;

- polished;

- electropolished

- Flange;

- milk screwing;

- tri-clamp;

- no-fitting;

- other

DIN; ISO; SMS; other

- Isolation;

- dirt storage tank;

- valve sluice for the sludge

The cyclone is a reliable device for dedusting gas streams from different types of particles. The geometry of a centrifugal dust collector depends on the gas stream, particle size and amount of contamination. These devices are used in many branches of industry. Depending on the destination, cyclones are made in different standards.