PRODUCTS IN CATEGORY

Efficient compressed air filtration – CLEARPOINT

Compressed air filtration is the process of removing aerosols, oil and particles in order to ensure the right quality – the class of compressed air. The CLEARPOINT compressed air filter – BEKO Technologies – provides reliable and effective protection of production equipment and end products against all contamination from the ambient air and compressor. The great advantage of CLEARPOINT filters is probably the lowest pressure drop they generate and thus considerable energy savings.

CLEARPOINT 3eco filter elements are selected to achieve any compressed air purity class – depending on requirements. They are able to retain contaminants such as aerosols, particles, dust, steam, odors and water. They achieve air purity class 1.-.1* according to ISO 8573-1 (Note class 1 is only possible if use of carbon and dust filters – coalescing cartridges are not able to stop oil vapours).

The CLEARPOINT – Beko Technologies range of compressed air filters includes, apart from standard filters, also high pressure filters (100 – 500 bar) and one of the best cyclone separator on the market, which, thanks to its design, has a very wide spectrum of operation. It is ideally suited for operation with variable-speed compressors.

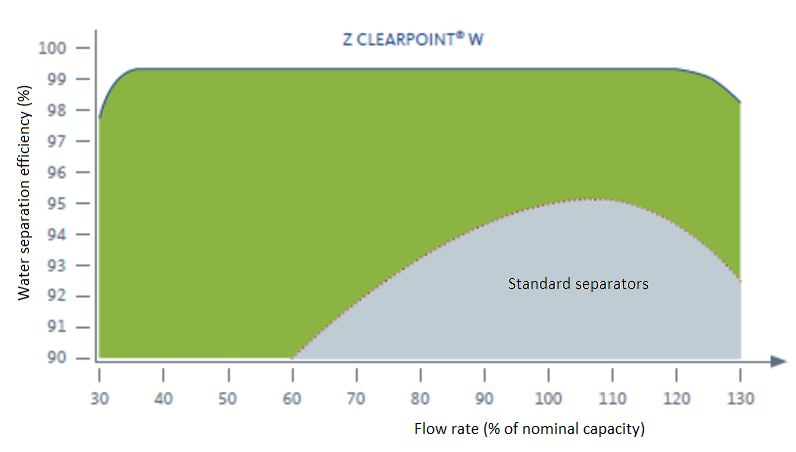

Performance graph – cyclone separator CLEARPOINT W

The cyclone separator (cyclone) – CLEARPOINT W – reaches its full efficiency at as little as 35% of the nominal flow, while most competing solutions only start operating at about 60% of the nominal flow. This is a very efficient product and does not require any operating expenses (apart from the periodic service of the automatic condensate drain, which must be installed on it).

From 46 m3/h to 34 680 m3/h

To 500 bar

- From 3/8” to 3” (thread)

- From DN80 to DN300 (flange)

From 0,01um to 25um

Differential pressure gauges and condensate drains (automatic – BEKOMAT and float)

Selection of an appropriate filtration system solution – after consultation with the customer in terms of the required quality and energy savings.

- Coarse filtration for non demanding applications (for air class 4:-:4)

- Fine filtration for more demanding installations (for air class 2:-:2)

- super fine filtration for the most demanding applications (for air class 1:-:2)

- super fine filtration with oil-free and odorous filtration (for air class 1:-:1)