PRODUCTS IN CATEGORY

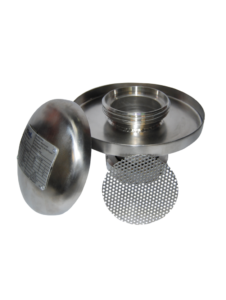

A breathing filter housing is often installed complete with breathing valves to compensate for pressure in the tank, e.g. when filling or emptying it, to prevent explosion or implosion. The installation of such a set therefore ensures that the tank is protected against damage due to overpressure or underpressure exceeding an acceptable value, while protecting its contents.In the food, pharmaceutical and biotechnology industries, the sterilization class breathing filter plays the most important role as a mechanical barrier and protects the tank contents from microbiological contamination. Such a filter should be periodically sterilized. Typical types of connections to breathing filter housings are tri-clamp or milk screwing.

ADSORPTION BREATHING FILTERS

Adsorption breathing filters can play a twofold role in industry. First, they protect the contents of the tank from moisture and external contamination (both solid particles and gases). Secondly, they prevent the vapours of the stored liquid from getting outside, which is particularly important when storing hazardous substances. For safety reasons (risk of explosion due to changes in pressure), the tanks cannot be completely separated from their surroundings, so it is necessary to use suitable filters. The operation of a device such as a breathing adsorption filter is based on the adsorption phenomenon in which particles, atoms or ions are bound to the surface of the adsorbent. Various deposits, e.g. activated carbon, silica gel, molecular sieves, may be used as adsorbent. The deposit is selected depending on which substance we want to adsorb.

BREATHING FILTERS FOR DEMI WATER

Demi water breathing filters are a special kind of adsorption breathing filters and are primarily used to adsorb carbon dioxide. When water is taken from a reservoir, it is exposed to the CO2 contained in the air, which in the case of demineralised water is a very undesirable phenomenon. The deposit used in devices such as breathing filters for demi water is zeolites, which are molecular sieves capable of adsorbing CO2. Breathing filter housings are made similarly to standard adsorption filters. Breathing filters can also be used to protect demineralised water in the tank from external factors. The top of the filter allows the water vapour to condense when there is hot water in the tank. The design of the breathing filter also has a special connection for condensation drainage.

- 1

- 10”

- 20’’

- 222

- 226

- DOE

- other

- AISI 304, AISI 316,

- satin;

- polished;

- electropolished

- Tri-clamp;

- milk screwing;

- other

DIN; ISO; SMS, other

Breathing filters are of great importance in many industries. They protect the contents of tanks from external factors, preventing contamination from getting inside them. In the food, pharmaceutical and biotechnology industries, a sterilization class breathing filter plays the most important role, providing a mechanical barrier and protecting the tank contents from microbiological contamination. Such a filter should be periodically sterilized.